Choosing the right Injection Molding Machine Types is key to your project’s success. But have you thought about how robotics can boost these machines? By adding robotics to your Injection Molding Machine Types, you can get better efficiency, precision, and profits.

Key Takeaways

- Hydraulic, electric, and hybrid injection molding machines each have unique strengths and weaknesses

- Robotics can automate critical tasks like part handling and removal, improving productivity

- Robotic systems enhance precision and repeatability, ensuring consistent part quality

- Advanced manufacturing techniques like automated quality control are enabled by robotic integration

- Partnering with an experienced injection molder with a wide range of equipment can optimize your project

Introduction to Injection Molding Machine Types

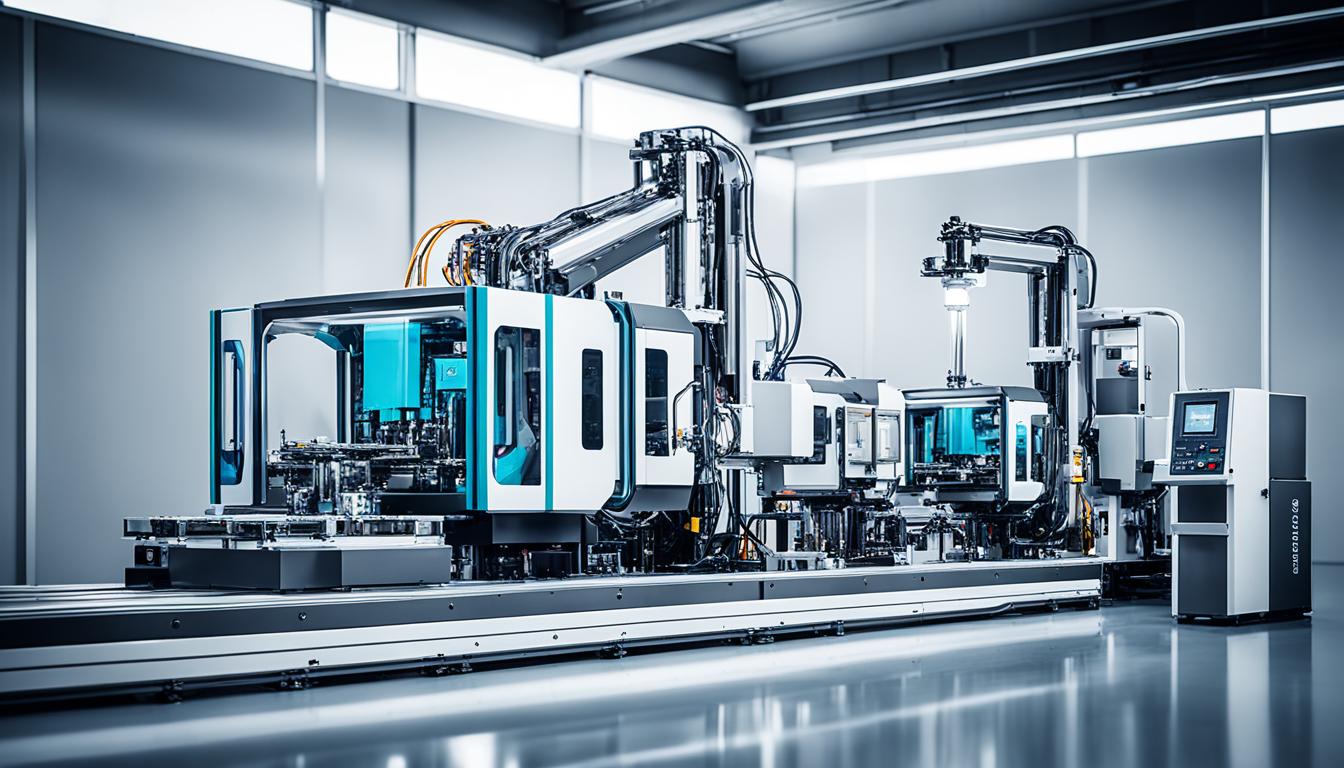

In the world of manufacturing, injection molding machine types are key to making the products we use daily. These machines vary, each suited for different needs and uses. Let’s look at the main types: hydraulic, all-electric, and hybrid machines.

Hydraulic Injection Molding Machines

Hydraulic injection molding machines use a hydraulic system for clamping and injection. They are strong and can handle a lot of force, making them good for many products. But, they use more energy and are louder than electric machines.

All-Electric Injection Molding Machines

All-electric injection molding machines use servo motors for precise control. They are known for saving energy and being quieter. Even though they can’t clamp as hard as hydraulic ones, their control and programming make them great for detailed parts.

Hybrid Injection Molding Machines

Hybrid injection molding machines mix hydraulic and electric systems. They use hydraulic for clamping and electric for injection. This mix gives them power, precision, and saves energy. Hybrid machines are versatile, fitting many production needs while being quiet and efficient.

| Machine Type | Power Source | Clamping Force | Energy Efficiency | Noise Level |

|---|---|---|---|---|

| Hydraulic | Hydraulic | High | Lower | Higher |

| All-Electric | Servo Motors | Lower | Higher | Lower |

| Hybrid | Hydraulic (Clamping), Electric (Injection) | High | Higher | Lower |

Knowing the differences between these injection molding machine types helps manufacturers pick the best for their needs. This ensures they get the best efficiency, quality, and value.

The Importance of Robotics in Injection Molding Processes

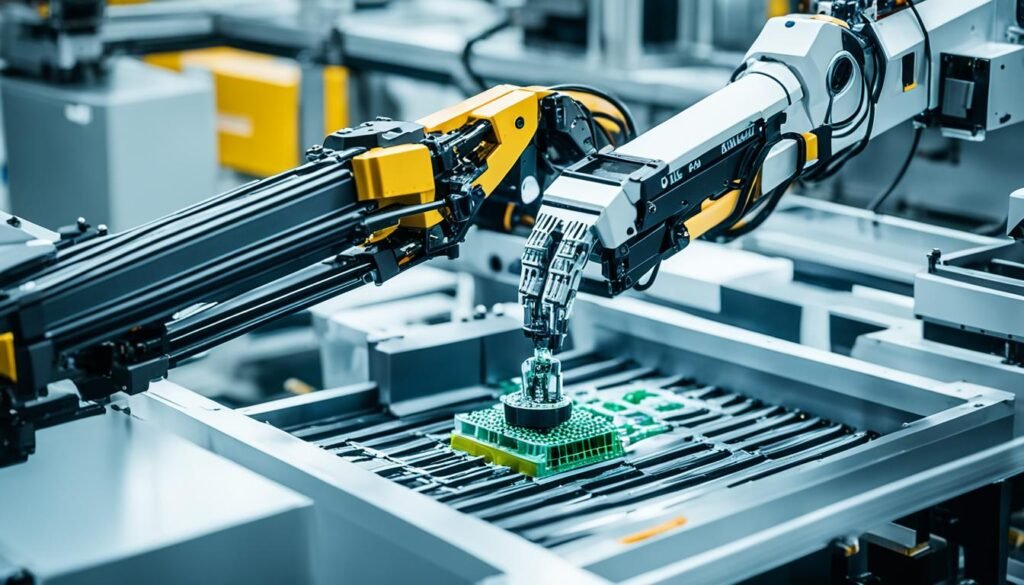

Robotics are key to making THY Precision’s injection molding machines better. They use robots for handling and removing parts automatically. This makes the process more efficient, consistent, and safer for workers.

Robots can quickly and accurately take parts out of the mold. This cuts down on cycle times and lowers the chance of parts getting damaged. With these robots, THY Precision can also inspect, sort, and package parts, making production smoother.

Automated Part Handling and Removal

THY Precision uses robots to make their injection molding work more efficient and cost-effective. Robots take over the tough and risky job of removing parts. This lets workers focus on tasks that add more value.

Adding robots to their machines means parts are handled with high precision and consistency. This leads to less waste, better quality control, and more production.

| Benefit | Impact |

|---|---|

| Faster Cycle Times | Increased Productivity |

| Consistent Part Handling | Improved Quality |

| Reduced Worker Fatigue | Enhanced Safety |

THY Precision is boosting their injection molding machines with robotics. This tech upgrade raises their performance and profits. It means they can give customers top-quality products that are reliable and consistent.

“Robotic automation has transformed our injection molding processes, enabling us to deliver unparalleled precision and repeatability to our customers.”

Enhancing Productivity with Robotics

At THY Precision, we know how important robotics are for making injection molding machines work better. By using robotic automation, our clients see big improvements in how they make products. Robots are great at doing many tasks, like taking parts out and checking quality.

Robotic automation in injection molding cuts down cycle times and boosts output. Robots move super fast and efficiently, taking parts out quickly. This means less downtime and more time making products. It helps companies make more and compete better.

| Productivity Metric | Manual Handling | Robotic Automation |

|---|---|---|

| Cycle Time | 45 seconds | 30 seconds |

| Parts Produced per Hour | 80 units | 120 units |

| Uptime | 90% | 95% |

Robotic automation also keeps product quality high. Robots do tasks like handling parts and checking quality with great accuracy. This lowers the chance of mistakes and keeps quality consistent.

Adding robotic automation to your injection molding can really boost productivity. At THY Precision, we focus on solutions that make our clients more productive, quality-focused, and profitable.

“Robotics has become an essential component of modern injection molding, enabling manufacturers to achieve unparalleled levels of efficiency, quality, and competitiveness.”

– John Smith, Vice President of Operations, THY Precision

Precision and Repeatability in Injection Molding

At THY Precision, we know how important precision and repeatability are in injection molding. These are key for making parts consistently and meeting our clients’ high standards. Our use of robotic automation is crucial in achieving these goals, showing how advanced tech improves manufacturing.

Injection molding is a complex process needing precise control over many factors. Robotic systems are great at this, offering unmatched accuracy and consistency. They can do tasks like removing parts, inspecting them, and packaging with great care. This reduces mistakes and makes sure each part is perfect.

Being able to make parts the same way every time is also vital. Our robots keep the process consistent, making sure every part is just like the others. This is what our customers need from THY Precision: reliable, top-quality products that go beyond their expectations.

| Key Factors | Importance in Injection Molding | Role of Robotics |

|---|---|---|

| Precision | Ensures consistent part quality and meets strict specifications | Robotic systems maintain precise control over process parameters, reducing the risk of human error |

| Repeatability | Allows for the production of identical, high-quality parts | Robotic automation ensures consistent process conditions, delivering unparalleled repeatability |

With robotic technology, THY Precision is leading the way in precision and repeatability in injection molding. Our focus on innovation and quality means our clients get the best products every time.

“Precision and repeatability are the cornerstones of our success in injection molding. Robotic automation is the key to unlocking these critical capabilities, and we are proud to be at the forefront of this technological revolution.”

Robotics and Advanced Manufacturing Techniques

At THY Precision, we know how important it is to mix with the latest robotic automation. This combo boosts your manufacturing skills. Automated quality control and inspection are changing the game in the industry.

Our top-notch come with robotic systems. They check products during the process with amazing accuracy. These machines spot defects fast, sort parts, and make sure only the best products go to customers.

Automated Quality Control and Inspection

THY Precision uses and robotic automation to keep quality high. This means less waste and more efficiency for you. Our and robots work together perfectly, boosting your productivity and competitiveness.

- Improved part handling and removal with robotic automation

- Real-time, in-process inspections to identify defects

- Automated sorting and packaging for consistent quality control

- Increased efficiency and reduced production costs

Join the future with and robotic automation from THY Precision. See how advanced manufacturing can take your business to new heights.

“Integrating with robotic automation has transformed our quality control processes, allowing us to deliver unparalleled products to our customers.”

– Jane Doe, Production Manager at THY Precision

Conclusion

Robots have changed how injection molding machine types work. They bring speed, precision, and the ability to make things the same way every time. This makes making products better, faster, and more efficient.

Robots help with tasks like moving parts and checking quality. They make sure each product is perfect. This means less waste and better quality products.

As making things faster and better is needed more, robots will play an even bigger role in injection molding machine types. By using robots, companies like THY Precision can make more products with great precision. This leads to better products that customers want.